Monitoring railway installations

Monitoring and maintaining the health of railway facilities is a key element of the technological progress of the industry, which is why continued investment in these types of devices is necessary. These include condition-based detection systems, data warehouses, and Big Data systems that support data mining and advanced analysis, all aimed at supporting the health of rolling stock and tracks.

Railway installations monitoring

Today, the industry has proactive and condition-based monitoring available that helps maintain a safe and efficient railway network. Thanks to more sophisticated detection systems, tracking of critical components of railway rolling stock, improved operational practices, and advanced analysis, potential mechanical problems can be recognized much earlier than in the past, generating an unimaginable amount of usable data already just 10 years ago.

In addition, the continuous investments of the railways in detection systemsThe continuous development of new types of detectors, the improvement of field inspection quality, and new analyses have allowed potential problems of railway carriages to be identified before service disruptions occur, reducing management costs and repair times on individual networks.

How advanced technologies are improving train safety and reliability

Railway facility monitoring systems and technologies are becoming increasingly sophisticated and advanced. These systems allow railway companies to monitor the health and functioning of railway facilities in real-time, improving the safety and reliability of trains.

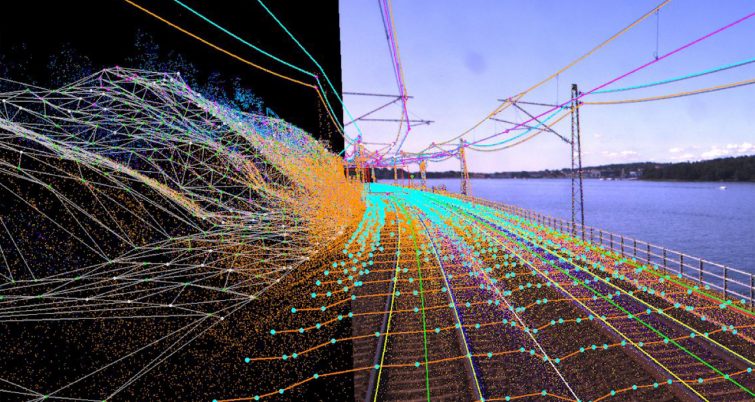

One of the main advantages of railway facility monitoring systems is the ability to detect problems and malfunctions before they become critical. Sensors and monitoring technologies allow for the detection of any anomalies or issues in railway infrastructure, such as track or signaling system wear. This information can be used to schedule preventative maintenance and prevent sudden failures, reducing train downtime.

Moreover, monitoring systems can help improve train reliability. For example, GPS technology can be used to monitor the position of trains and predict any delays or issues on railway lines. In this way, railway companies can provide passengers with real-time information on the status of their journeys and improve the overall passenger experience.

Other technologies used for railway facility monitoring include the use of cameras, temperature and pressure sensors, and data analysis software. These tools allow for the monitoring of railway infrastructure, improving safety and preventing potential failures.