LiDAR: how the use of this technology is revolutionizing remote sensing and improving safety in railway infrastructures.

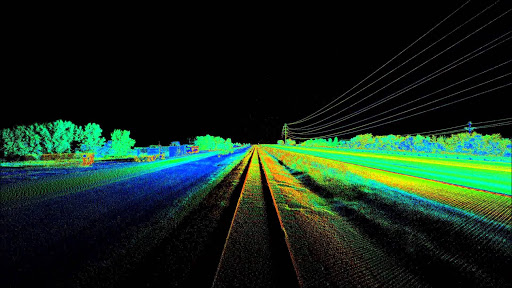

LiDAR (Light Detection and Ranging) is a form of remote sensing that uses laser light pulses to gather information from surfaces in the form of “points” (3D coordinates). The data is processed with software to create a digital CAD model of the scanned environment. Data collected during LiDAR surveys and the resulting 3D digital model can be used to analyze current railway conditions, identify safety risks, and plan the construction of new lines and structures.

LiDAR has become commonly used and is growing. Transport agencies, governments, and construction companies around the world are using it to streamline processes and increase safety levels.

Lidar, the new frontier of remote sensing

LiDAR applications

Calculation of MAS: Once LiDAR data is collected from a railway route (or a potential route), 3D processing software is used to automatically calculate the MAS (maximum authorized speed) for curves, which is essential for preventing loss of control and derailments caused by overspeed conditions, while also improving ride quality and passenger comfort.

Identification of the right-of-way encroachment.

Occasionally, vegetation or even artificial structures (fences, shifted service poles, etc.) can encroach on railway corridors, creating a safety hazard. At highway and railway crossings without active warning devices, such encroachment can limit drivers’ view of the right of way and increase the risk of collision. LiDAR surveys can identify such encroachments, and once located, detailed measurements of the encroachment can help mitigate the risk.

Analysis of the conditions of the roadway and roadbed.

Data collected during LiDAR scans also provides detailed information on the condition of road surface and bed degradation.

Rapidly identifying issues means they can be addressed immediately before track conditions create a service disruption, or worse, a derailment. By analyzing the existing profile of the track and comparing it with an idealized profile, structural deficiencies can be identified before they fail.

Gesa Industry adapts and renews projects with the latest technologies.

To always guarantee an excellent level of quality Gesa Industry, In the process of designing and planning train interiors, LiDAR can also adapt and renew designs to accommodate all the latest technologies in comfort and safety, adopting cutting-edge components capable of meeting increasingly high quality standards.